Complete 150,000 TPY 8-32mm Hot Rebar Rolling Mill For Sale

- Hot rebar rolling mill plant finished product size: 8 mm to 32 mm hot rolled rebars.

Raw material: scrap (120*120mm continuous casting billet)

Details Description

The product line is for the hot rolled bar. The main process is that the raw material of continuous casting billet by burning gas heating furnace is heated to a suitable temperature, the conveying roller feeding 450mm bloomer roughing mill, after seven passes rolling into the finishing rolling group and then become a straight rod product, after stepping cooling on cooling bed, then be divided by the multiple shear, collection packaging, and storage.

Raw material: scrap (120*120mm continuous casting billet)

Finished product: 8-32mm hot rolled rebar

Designed productive: 150,000 tons/year

Process Flowing:

Smelting — continuous casting — 3hi roughing mill — hydraulic cutting — medium mill group — accident cutting — finishing mill group — multiple shearing — cooling — fixed size shearing — collecting — packaging — inspection — labeling — be put into storage

Hot Rebar Rolling Mill Reheating Furnace

100t / h Push Steel Reheating Furnace.

Blank section specification: 150mm × 150mm

Billet length: 12m

Loading method: single row

Steel grade: high-quality carbon steel, low alloy structural steel.

Stove form: end feed, side discharge, air heat exchange push steel heating furnace.

Heated steel: high-quality carbon structural steel, low alloy structural steel;

Billet heating furnace temperature: 1100-1150°C

Fuel: natural gas

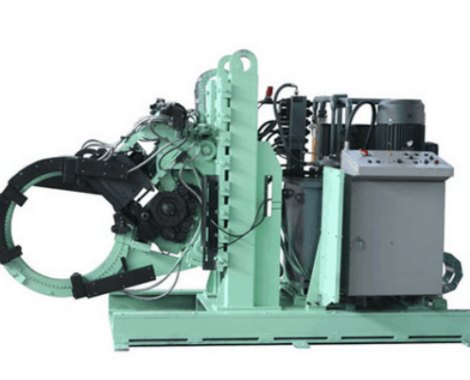

Automatic TMT Rebar Bundle Tying Machine

Automatic TMT Rebar Bundle Tying Machine

Twisted wire twist angle: 630

Single tie time: 7 – 12s

Suitable for: 10-40 thread steel

Contact Us