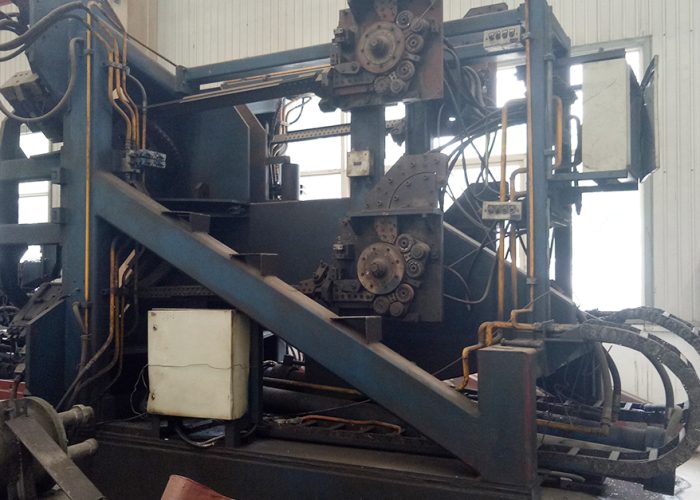

- Composite high speed wire rod & rebar production line adopts φ285 and φ230 finishing mill group without twisting.

- The rolling mill machine of the production line can be horizontal mill, vertical mill and the top cross type with tungsten carbide roll ring.

Details Description

Composite high speed wire rod & rebar production line is customized for small and medium plants whose required annual capacity is 300, 000 tons – 500, 000 tons, fully taking into account the investment capacity of steel company, the size of the plant scale and other conditions.

For the new production lines, one production line of investment available to achieve the output of high speed wire rod and rebar. Composite high speed wire rod & rebar production line can help steel plant avoid duplication of investment, ensuring the equipment operating rate.

For old retrofit line, we can make full use of existing equipment and space, with a small investment producing the original single varieties developed into a variety of specifications of products, making economic benefits increasing doubly.

Composite high speed wire rod & rebar production line adopted low-power, high-speed design, process arrangement. Compared with traditional two lines, it can reduce the energy consumption of 1/3 to 2/5.

Parameters:

A composite high speed wire rod & rebar production line can roll out of a variety of specifications of wire rod and rebar products:

Small diameter of steel bar: φ8/φ10/φ12/φ14/φ16

Large diameter of round bar and deformed steel bar: φ18-φ32

Wire rod specification: φ5.5/φ6.5/φ8/φ10/φ12/φ14/φ16

Composite high speed wire rod & rebar production line adoped quick-change , fast transfer design, easy replacement of product variety, fast, reliable, simple and easy to master.

Steel enterprises can flexibly adjust product specifications according to market demand, maket in control!

Flying Shearing Machine

Flying shear is composed of transmission equipment, cutting support base and upper & lower spindle. Upper spindle has optical-electricity-encoder to control the start-stop position of the shear blade in the processing of the cutting. It is behind conveying guide groove, for cutting head of rolled piece and emergency accident.

Increasing Gearbox Units

Increasing Gearbox Units consist of case group, base, gear, drive shaft, bevel gear shaft and box lubrication system components. The Large main motor drives two output shafts which drove by rack wheel, associated by gear-type coupling and two drive shaft, respectively driving the racks of right and left sides.

Contact Us